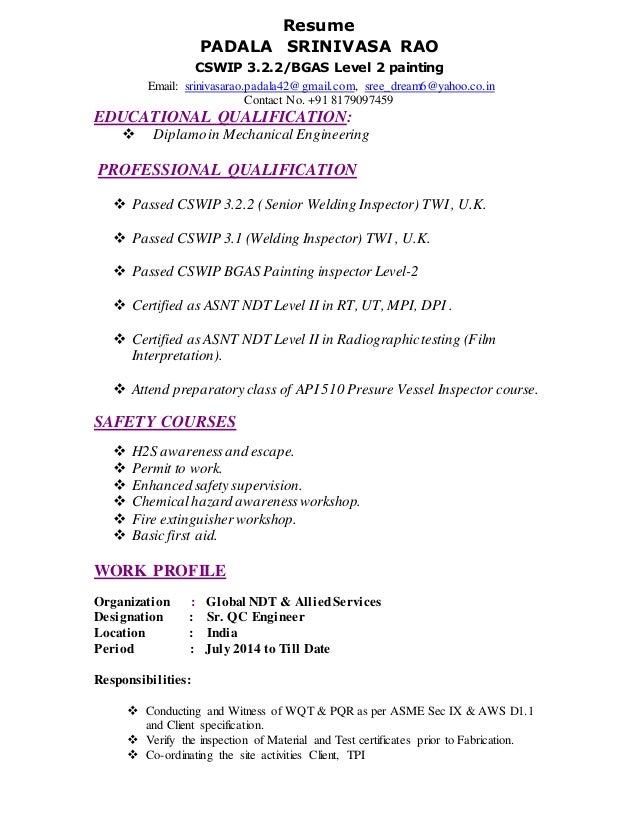

CSWIP 3.1 CSWIP 3.2 CSWIP 3.1 / 3.2.2(Welding Inspector, Level 2 / 3) Preparatory courses, Seminar Examination program BIT Inspection Technology focus with sincerity and authentic approach in giving new dimension to Welding Inspection Training. Our welding inspection Training Center is equipped with adequate infrastructure to provide both Theoretical and Hands –. From 21 – opening the “CSWIP 3.1 – Welding Inspector Level 2” course. Suitable for: Inspection engineers and supervisory staff. The course is ideal for inspectors requiring preparation for the CSWIP examinations – Welding Inspector. To join this course you must have been a Certified Welding Inspector for a minimum of 2 years with job responsibilities in the areas listed in 1.2.1, 1.2.2 and 1.2.3 of CSWIP document WI-6-92. Alternatively, you should have 5 years' authenticated experience related to the duties and responsibilities listed in Clause 1.2.3 of CSWIP document WI-6. CSWIP 3.1 – Welding Inspector – Level 2. (Blended Training On-line KELAS MALAM) CSWIP 3.1 – WELDING. November 4, 2020 Welding Inspection 3in1 Bali.

Cilegon,

September, 21st – 26th 2020

Cswip 3.1 Level 2 Exam Paper

Next Schedule :

December, 14th – 19th 2020

Note : Registration 1 month before course date

(5 days course and 1 day examination)

Course and exam fee =

Rp. 30.000.000,- (Include Tax)

*Registration 1 months before course date,

Minimum payment for registration (Rp. 7.000.000,-)

Suitable for :

Inspection engineers and supervisory staff. The course is ideal for inspectors requiring preparation for the CSWIP examinations – Welding Inspector.

Those with little or no previous welding experience are advised to attend the Certificate in Visual Inspection of Welds course to prepare for this course.

Course Content :

The duties and responsibilities of a welding inspector; fusion welding processes; typical weld defects; types of steel; carbon-manganese, low alloy and stainless steels; hardening of steels; weld ability; heat treatment; parent metal defects; visual inspection; testing parent metals and welds; destructive tests; NDT techniques; welder and procedure approval; codes and standards; outline of safe working practices; practice in examination questions; continuous and end-of-course assessment. In addition, candidates meeting the CSWIP requirements for eligibility complete the relevant CSWIP examination on day 5.

Course Objectives :

To understand factors which influence the quality of fusion welds in steels

To recognize characteristics of commonly used welding processes in relation to quality control

To interpret drawing instructions and symbols to ensure that specifications are met

To set up and report on inspection of welds, macro sections and other mechanical tests

To assess and report on welds to acceptance levels

To confirm that incoming material meets stipulated requirements and recognize the effects on weld quality of departure from specification

To be in a position to pass the Welding Inspector – Level 2 examinations

Additional Information :

Call +62-8111788615 (HELMAN)

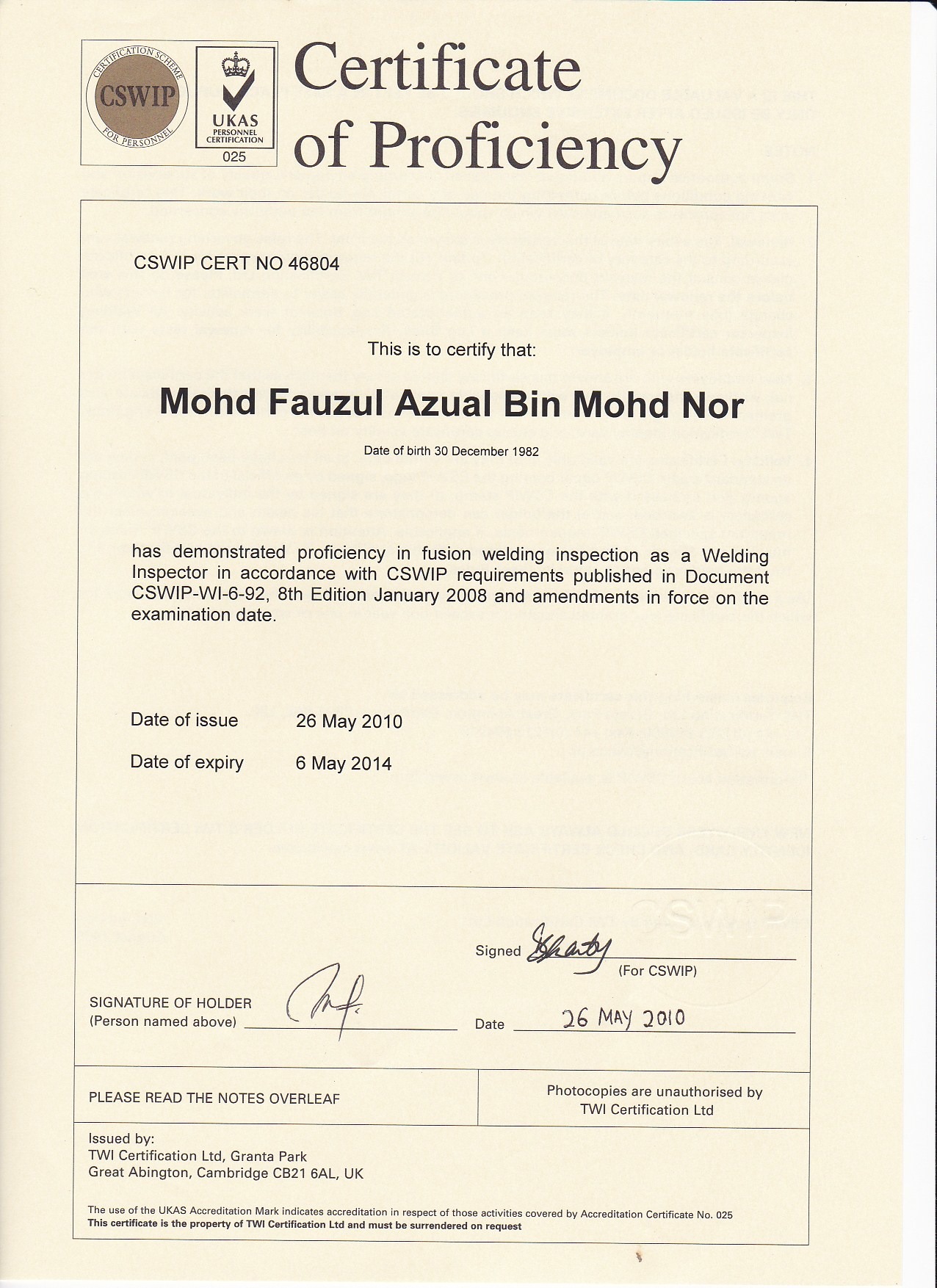

CSWIP Welding Inspector examination – All candidates must attend a CSWIP approved course of training prior to examination. Enrollment on this course does not constitute reservation of an examination. All courses may be followed by a CSWIP Welding Inspector examination for candidates with appropriate experience as specified in CSWIP document WI-6-92. All CSWIP documents are available at www.cswip.com.

ENTRY REQUIREMENTS :

Welding Inspector for a minimum of 3 years with experience related to the duties and responsibilities listed in Clause 1.2.2 of CSWIP document WI-6-92, under qualified supervision, independently verified

OR

Certified Visual Welding Inspector (Level 1) for a minimum of 2 years with job responsibilities in the areas listed in 1.2.1 and 1.2.2 of CSWIP document WI-6-92

OR

Cswip 3.1 Level 2 Dfd

Welding Instructor or Welding Foreman/Supervisor for a minimum of 5 years

Pendaftaran

Email : [email protected]

Mobile : +62 811 838 1232

Phone : +62 254 8481815